The key to strengthening brittle materials New gel maintains long-term strength and toughness

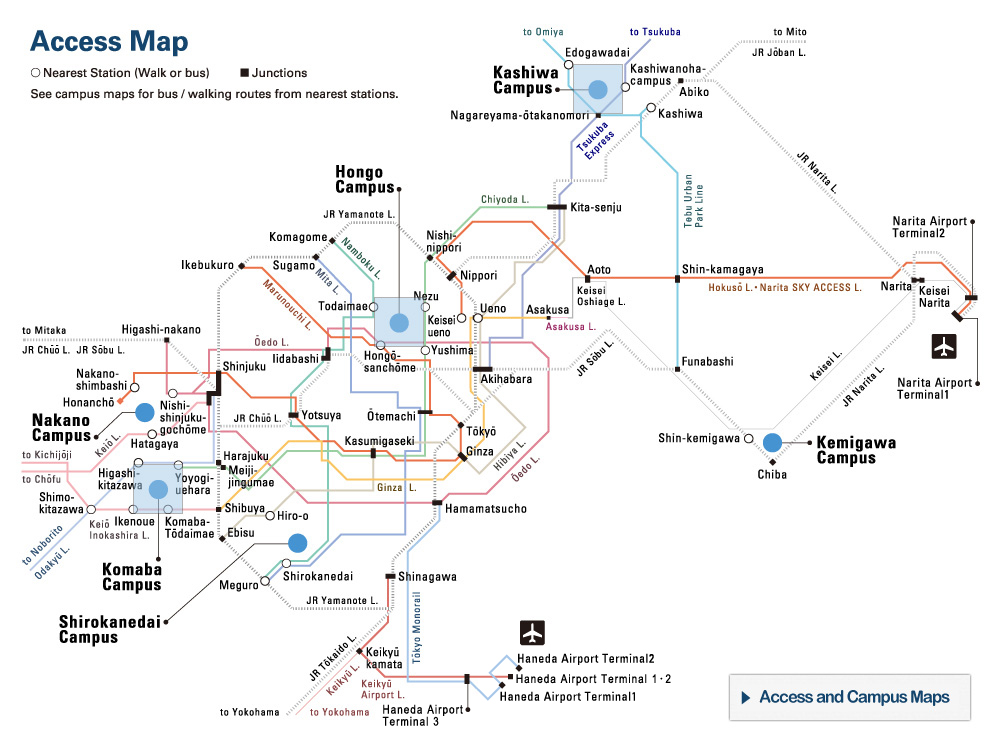

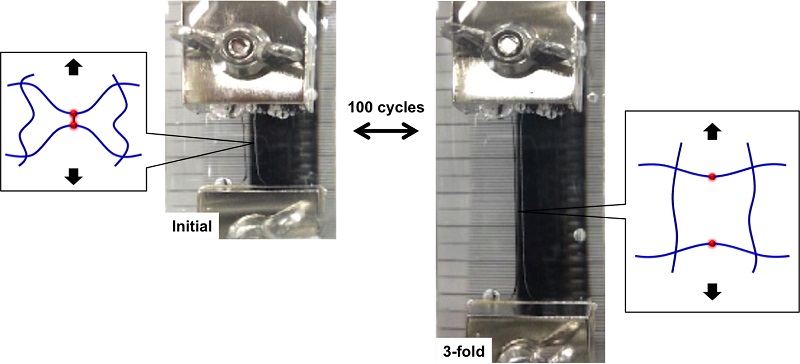

Structural change in the network structure of the gel under the cyclic stretching test

(Left) The unstretched gel in an aqueous environment. (Right) The gel repeatedly stretched to three times its initial length in an aqueous environment. When the new gel is subjected to an external force, aggregates in the network preferentially break prior to the breakage of the permanent network, dissipating energy.

© 2015 Takamasa Sakai.

Researchers at the University of Tokyo have developed a gel that retains its shape when molded and maintains its strength and flexibility for a long period by purposely introducing plastic properties to the gel. The new material should find applications in challenging environments such as load-bearing medical implants including artificial muscle and cartilage or discs for artificial knee joints that are exposed to repeated stretching and bending.

Gels are soft materials composed of a 3D polymer network that contains solvent. Owing to their unique features such as flexibility and solvent retention ability, gels are widely used from commodities including foods and cosmetics to medical and sanitary products including contact lenses and diapers. However, conventional gels are not reliable enough for use as structural materials, because they suffer sudden breakage when exposed to repetitive load.

A University of Tokyo Graduate School of Engineering research group led by Associate Professor Takamasa Sakai has developed a new gel with plastic properties by uniformly introducing special polymer chains in the network, which spontaneously form aggregates in an aqueous environment. They have found that their new gel maintains its strength and flexibility for a long period of time. In an aqueous environment, the uniformly distributed aggregates reinforce the permanent network of the gel. When the gel is subjected to an external force, aggregates in the network preferentially break prior to the breakage of the permanent network, effectively dissipating the energy transferred by the applied force. This plastic property of the aggregates provides the gel with sufficient strength and toughness to endure repetitive elongation or compression.

“Conventional gels will break if extended several times in an aqueous environment, but our gel can survive being repeatedly extended to three times its original size over 100 times,” says Associate Professor Sakai. He continues, “In addition, the preparation method is easy, and anyone can produce it simply by mixing two solutions.”

Paper

, "Reliable gel with mechanical ‘fuse link’ in an aqueous environment", Advanced Materials Online Edition: 2015/10/07 (Japan time), doi: 10.1002/adma.201503130.

Article link (Publication)

Links

Graduate School of Engineering

Department of Bioengineering, Graduate School of Engineering

Sakai-Tei/Chung Laboratory, Department of bioengineering, Graduate School of Engineering