Earthquake disaster reconstruction activities have triggered a shortage of concrete in the Tohoku Region. The government is advancing establishment of public plants for ready-mixed concrete, which has a limited lifespan, but at the same time, a number of researchers have launched practical initiatives in order to prevent hasty and low-quality mass construction. Buildings have a long in-service period, and when construction work is implemented without consideration of quality and with focus only on quantity, such a failure to follow the teachings of our predecessors usually proves costly in the future. In the second half of Japan's period of rapid economic growth, Japan experienced grave problems caused by early deterioration of structures that were rapidly built through the automation of construction methods.

Correct understanding not only of construction materials, but also of construction formats is necessary in order to ensure the long-term safety of buildings. The accident in which concrete slabs collapsed from the ceiling of the Sasago Tunnel on the Chuo Expressway is still fresh in our minds. Those in charge of the tunnel's maintenance should have understood its construction format and employed creative and innovative approaches in order to accurately grasp the risk factors involved that may lead to possible future deformations. Even with regular inspections, such accidents cannot be prevented unless people learn to pay attention to the latent yet grave risks to safety. The aging degradation of materials is one of the factors affecting safety and all possible risks should also be envisioned and taken into account. Failure to provide sufficient projections with regard to all possible scenarios just because they are beyond the scope of assumption is inexcusable.

Japan has already entered a period where it must maintain and manage existing infrastructure. Palliative repair work that does not thoroughly eliminate the causes of deformation is meaningless as similar deformations are bound to occur over and over again. Some have theorized that the financial burden of maintaining and managing its extensive infrastructure led to the demise of the Roman Empire. Safety does not come free. It is essential to maintain an adequate balance between safety and costs. Engineers must be able to perceive with precision the severity of the possible consequences from neglecting a deformation and appropriately identify the seriousness of any situation. Some types of Roman concrete, which were used in the building of the Pantheon, have survived intact through the ages. Concrete, which today is synonymous with public construction projects, has a vital mission: to support social activities across generations and ages.

Self-healing of expansive concrete with a low water/binder ratio (first generation)

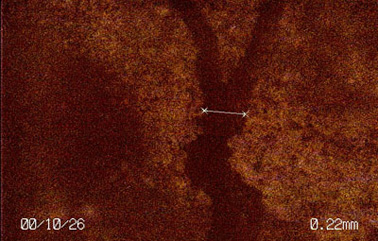

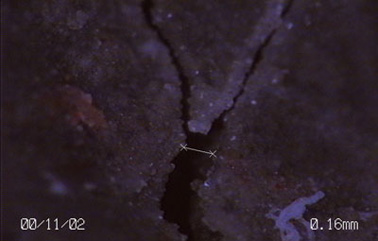

The picture shows first-generation crack self-healing concrete from the research project that we implemented around 2000. We used high-strength high-fluidity concrete with a lower than normal water-to-cement ratio (water/binder ratio), and added more than the standard amount of expansive agent. On the eighth day of the material age, we made cracks in the concrete and immersed it in water. Approximately one month later, the cracks closed almost entirely. Today, we are advancing development of fourth-generation technology that incorporates a semi-capsulation effect. © Toshiharu Kishi.

Concrete is a composite material that consists essentially of cement, water, and aggregate. In combination with reinforcing steel or other steel stock, it is used as a composite structural material. Concrete hardens as a result of hydration: the chemical reaction between cement and water. However, as the calcium hydroxide and other cement components in the concrete come in contact with the air, they gradually react with the carbon dioxide present in the atmosphere and attempt to revert back to limestone, the main ingredient of cement. This reaction is called lithification and serves to enhance the stability of concrete. In the case of reinforced concrete, however, lithification is accompanied by loss of alkalinity, which protects the reinforcing steel from corrosion, and, therefore, is considered a degradation phenomenon known as neutralization of concrete. There are many other degradation phenomena, such as salt damage, alkali-aggregate reaction, frost damage, chemical corrosion, and fatigue.

Concrete is an affordable and easily-accessible construction material, but the fact that it is so common does not mean that it is a simple substance. Concrete is a porous material and contains numerous pores of broadly varying sizes, from several nanometers to several millimeters. Their interconnected structure and the behavior of water and ions in the pores are quite complex. The fact that it takes several years for a 1 mm-thick cement paste specimen to dry is explained by the complex connectivity among pores which is influenced by the ink-bottle effect. The macro degradation phenomena that occur in concrete are the result of movements and reactions among elements within its complex porous structure. Bulk water is a Newtonian fluid, but in micro-pores it behaves differently. The changes extend beyond a simple increase in viscosity, and the rule that fluid velocity is proportionate to the pressure gradient is no longer valid. The movement of ions in micro-pores cannot be explained simply as diffusion and advection, and the scenarios differ depending on whether pores are saturated with liquid water. Simple diffusion may not occur even if water fills the pores, due to the complex connectivity among pores and the impact of electrical double layers.

This complex structure of concrete makes accurate prediction of its aging degradation quite difficult. The general approach in durability design of modern buildings is to project a design service life of 100 years. A hundred years may seem easy enough, but consider the fact that 100 years ago Japan was still in the Meiji and Taisho (1868 - 1926) periods. Concrete may also be used as a material for building underground repositories for radioactive waste with a half-life that reaches into the tens of thousands of years. In order to make accurate quantitative projections of all possible scenarios involved with such utilization, it is necessary to have a correct understanding of the process of formation of pores in concrete and the behavior of elements in micro-pores, and visualize it through elaborate simulation models. Exploring the true nature of things is a cornerstone even in engineering.

Society is facing a broad range of issues, and solving them is one of the missions entrusted to engineering. We must produce solutions using present levels of knowledge, and under various restrictions, so it is crucial to maintain proper balance and clarity. These limitations, however, could be overcome through research and technology development. Exploration of the true nature of things and technology development are two extreme opposites but at the same time they are like two sides of the same coin. Exploration of mechanisms could trigger a breakthrough in technology development, and the development process could in turn deepen the understanding of such mechanisms. Contrary to some expectations, development of practical elemental technology and academic composite technology is seen as a niche endeavor. One of the lessons I have learned from my senior mentor is that engineers can contribute to society in various ways, but researchers must aim to promote the extremes of both research and technology development, otherwise their efforts will be meaningless. Additionally, it takes about 10 years to complete a single research project. That is why the best approach is to advance three research projects simultaneously by adjusting their phases of germination, development, and deployment. This is another lesson I have learned from my senior mentor. 15 years have already passed since I started research and development of crack self-healing concrete. It is easy to understand what my senior mentor was trying to convey, but it is difficult to apply this in practice.