Room Temperature Bonding of Film-to-Film and Film-to-Glass without Adhesive

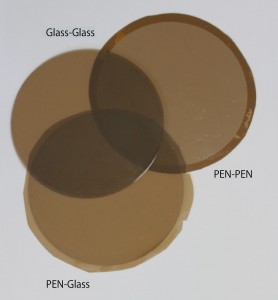

Polyethylene Naphthalate (PEN) and glass bonded by the modified surface activated bonding (SAB) method.

© Tadatomo Suga

Professor Tadatomo Suga and his research group, together with Lantechnical Service Co., Ltd (President: Yoshiie Matsumoto), have proposed a novel modified surface activated bonding (SAB) method for room temperature bonding of polymer film to polymer film and polymer film to glass without the use of adhesives. SAB is a process that joins similar or dissimilar materials by means of the adhesion force acting between atoms of two atomically cleaned surfaces created by argon (Ar) ion beam bombardment in an ultrahigh vacuum at room temperature. Various materials including silicon (Si) and copper (Cu) can be bonded successfully by the SAB method. However, in the case of polymer films, the film surface is damaged by Ar ion beam bombardment resulting in a very low bonding strength. In this study, polymer films such as polyethylene naphthalate (PEN), polyethylene terephthalate (PET), and KaptonR polyimide, were bonded to non-alkali glass wafers by the modified SAB method. An intermediate 10nm-Si layer and an iron (Fe) nano-adhesion layer of less than 1nm thickness were deposited prior to the bonding in order to avoid to reduce any damage to the film surface and to strengthen the bonded interface. The bonded interface is expected to have very low gas permeability because of the very thin nanometer-scale interface created without adhesive, which should provide a sealing technology suitable for OELD or solar cells applications.

Paper

Tadatomo Suga, Takashi Matsumae, Yoshiie Matsumoto, Masashi Nakano,

“Direct Bonding of Polymer to Glass Wafers using Surface Activated Bonding (SAB) Method at Room Temperature”,

Proceedings of the 3rd International IEEE Workshop on Low Temperature Bonding for 3D Integration, May 22- June 23, 2012.

Article link

Links

Graduate School of Engineering

Department of Precision Engineering