Biofuel Researchers' keyword commentaries

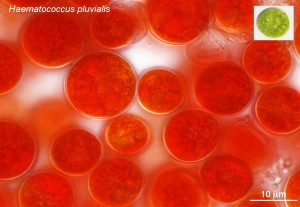

Figure 1. Haematococcus. This species, which is originally green, becomes red after accumulating astaxanthin when cultivated under strong light. Astaxanthin can be used as food coloring for chicken’s eggs and trout as well as antioxidant agent. The oil contained by the substance could also be used as a biofuel. There are also many other high-potential species that produce copious amounts of oil. © Shigeyuki Kawano.

Although I had been feeling gloomy after the accident at the nuclear power station in Fukushima, I felt better after I heard some good news from France: a leading European aircraft manufacturer (EADS) announced at the Paris Air Show that jointly with Japan they were developing a supersonic airplane that could fly from Tokyo to Paris in two and a half hours. Its greatest feature is that the Zero Emission Hypersonic Transportation (Zehst) plane will not emit CO2 because it uses biofuel derived from seaweed. A prototype will be completed by 2020 and commercial operation will start by 2050; it is expected that algae-derived biofuel will also be in wide use by that time (Table 1).

In recent years, against the backdrop of spikes in crude oil prices, global warming, and the use of cereals in the production of bioethanol, both public and private organizations across the world are investing in research into biofuel derived from seaweeds and microalgae. There are high expectations for biofuel, as the case of the Zehst airplane shows. Biofuel research has progressed considerably. The first-generation biofuel (bioethanol, which was developed despite a range of problems) has been successfully developed, and speedy efforts have been made to put the second-generation biofuel, derived from camelina, jatropha and algae, into practical use. Compared with other plants, the productivity per area for algae is excellent, and it can be cultivated even in areas unsuitable for agriculture, thus not leading to a decrease in the farmland available for food crops. Algae are therefore high among the potential candidates for biofuel, and we are able to choose the most productive algal species for the local environment from among a variety of genetic resources (Figure 1).

| Item | Market size | Remarks |

|---|---|---|

| Biofuel | 128 to 1,105bn yen | World market (forecast for 2015 to 2020) (1) |

| Laver | 300bn yen | About 30,000 tons (2) |

| Kelp | 240bn yen | Domestic market (retail basis) (2) |

| Wakame seaweed | 50bn yen | Mostly farmed (97% of domestic production and 100% of imports) (2) |

| Chlorella | 30bn yen | About 1,000 tons (3) |

| Astaxanthin | 10bn yen | Materials: One ton (up 20% year-on-year) (3) |

| Fucoidan | 10bn yen | Domestic market (forecast for 2008) (3) |

| Euglena | 5bn yen | Domestic market (forecast for 2015) (4) |

| Spirulina | 800m yen | About 150 tons/year; 5,000 yen/kg (surveyed in 2009) |

| Fucoxanthin | 200m yen | About 0.5 tons/year; 150,000 to 300,000 yen/kg (surveyed in 2008) (3) |

| (1) Source: Global information, Inc.: http://www.gii.co.jp/press/sbi125952.shtml (2) Source: Sato, J. (2002) Processed seaweeds in “The situation of phycology at the beginning of the 21st century” edited by T. Hori, M. Ono, and T. Horiguchi, The Japanese Society of Phycology (Yamagata), pp 140?142. (3) Source: Genryobank http://www.genryoubank.com/ (4) Source: SankeiBiz November 3, 2010 |

||

Professor Shigeyuki Kawano

Plant Life System (Japanese)

Graduate School of Frontier Sciences

(This article first appeared in the tenth issue of Tansei.)