3D concrete printing design competition held

The Department of Architecture and the Department of Civil Engineering of UTokyo’s Graduate School of Engineering jointly held an industry–academia collaborative design studio course on 3D concrete printing (3DCP)* in the summer semester of 2022. The theme of the course was “Designing 3DCP benches to be installed at Futomi Station.” The first design competition in Japan regarding 3DCP was held through this course. Two benches selected in the competition were printed and installed at Futomi Station in Kamogawa, Chiba Prefecture, which is operated by the East Japan Railway Company (JR East) Chiba Branch Office.

Designs of benches proposed in the first competition in Japan regarding 3DCP and their test–printed benches

The competition was organized in collaboration with the JR East and 4 construction firms that own 3D concrete printers – Aizawa Concrete Corporation, Polyuse Inc., Kurabo Industries Ltd. and JGC Corporation. All the companies are members of a technical committee of the Japan Society of Civil Engineers on 3DCP.

In the first lecture of the course, JR East introduced Futomi Station and its renovation project. Futomi Station is an unmanned station, two hours from Tokyo Station by train, and is located very close to the coast. Two benches to be installed in the renovated station were what the students were tasked with designing. JR East also explained the design requirements, including the need for low or no maintenance required during the benches’ service life, high durability against chloride damage**, and the need for a surface finish that would not tear users’ clothing. The 3DCP firms then introduced their technologies and explained the advantages and limitations of their printers and materials.

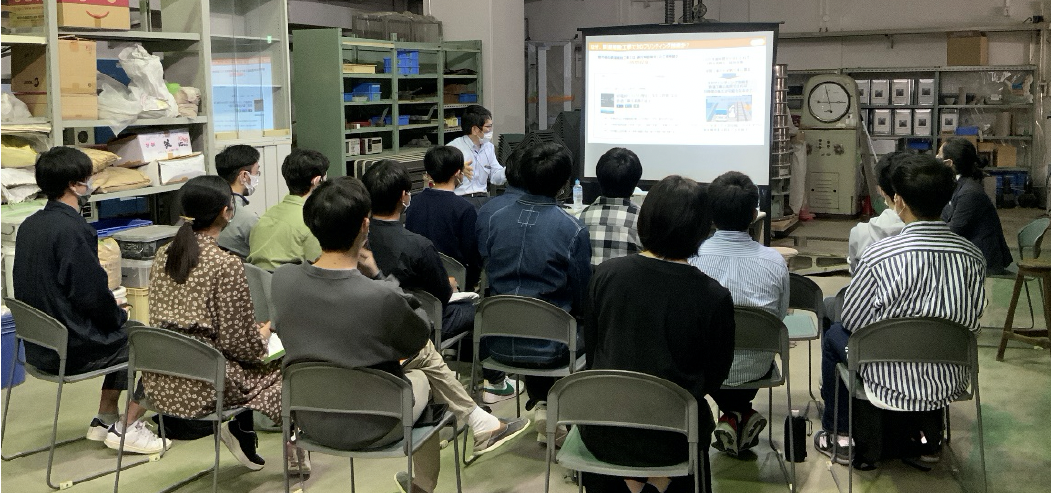

Beginning the following week, students in the studio visited a 3DCP facility, conducted some experiments in the lab, and had lectures and received advice on each of their design proposals from experts in various fields.

In the preliminary selection stage held in May 2022, 14 design proposals were submitted by students. The 3DCP firms then selected three out of the 14 designs, and students were divided into three groups, which teamed up with the four companies. Each team discussed technical and economic aspects of their design and submitted their final proposal in July (See the links below). In the final selection stage, the proposal by the student team with Aizawa Concrete Corporation was selected as the best design by the JR East Chiba Brach Office.

The selected benches were fabricated in Aizawa Concrete Corporation’s 3DCP factory, and the performance verification was also done by experiments in September. The benches were then delivered and installed at Futomi Station in October. The renovation project of the station was completed on December 14, 2022, when the new station building was opened, along with the new 3DCP benches.

Two 3DCP benches installed at Futomi Station

This is the first competition in Japan where multiple 3DCP firms joined and actual implementation of 3DCP technology was realized in an existing train station. Through this competition, information on the advantages and limitations of each company’s technology was shared, and the specific technological developments necessary to meet the client’s requirements were also clarified. In addition, the students were able to receive more practical education by not only thinking about the design, but also through discussion with the professional engineers, technical proposals to the asset owner, and through experiences in contracting, performance verification tests, execution and inspection.

This industry–academia collaborative course presents a fresh approach to education and is expected to promote the development and implementations of 3DCP, which should make a significant contribution to Digital Transformation (DX) in the construction industry.

Although the deliverables were just benches this time, 3DCP technologies will be applied to large-scale buildings and civil engineering structures in the near future.

* Abbreviation for 3D concrete printing. The most popular 3DCP process uses giant gantries or robotic arms and extrudes cement-based materials from the nozzle to fabricate the object layer by layer.

** Chloride ions contained in seawater make steel susceptible to rust. In the case of reinforced concrete, chloride ions penetrate through the concrete cover and significant corrosion occurs in the steel rebars, which can cause cracks in the concrete.

Presentations by the student teams (in Japanese)

・Team with Polyuse Inc.

https://youtu.be/y-Tr_G-kvLs

・Team with Aizawa Concrete Corporation

https://youtu.be/fUbT_t3HvTw

・Team with Kurabo Industries Ltd. and JGC Corporation

https://youtu.be/fg5ULGi64Ho