UTokyo researchers answer questions on 21 GX (Green Transformation) topics from their specialist viewpoints. Through questions that cannot simply be brushed off as someone else’s concerns, take a peek into GX and our world of research.

Q11. Is it true that we can still eat meat even if we stop raising livestock?

Some think that we eventually will have to stop eating meat in order to help the environment and protect animals, but apparently there’s cultured meat. What’s that?Answered by Shoji Takeuchi

Professor, Graduate School of Information Science and Technology

Mechanical Engineering

Aiming to culture thick steaks

Laboratories all over the world are currently racing to develop cultured meat as a means of reducing greenhouse gas emissions and countering food shortages. Expected to become one of the meat substitutes on offer as a replacement for traditionally reared meat, cultured meat is made by cultivating cells taken from a small amount of muscle tissue from a living animal. While there are various methods of producing what is known as cultured meat — one group even using the term to describe their mixture of large amounts of cultured meat cells with soy-based meat — our aim is to produce a thick chunk of meat like a steak carved from an animal’s body. Using cells from the original animal, we are investigating how best to create meat outside of the animal’s body.

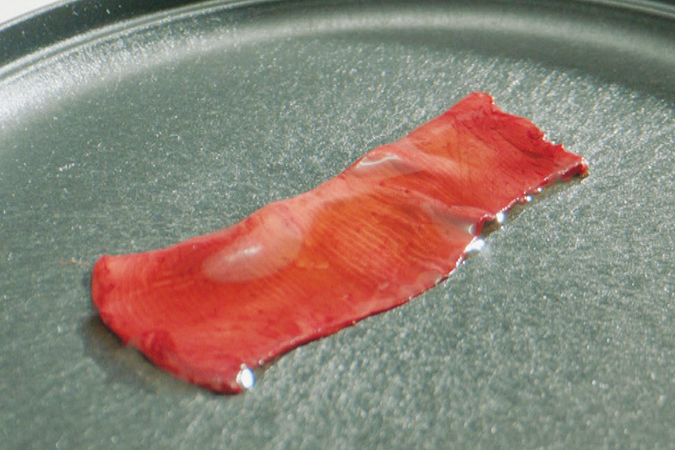

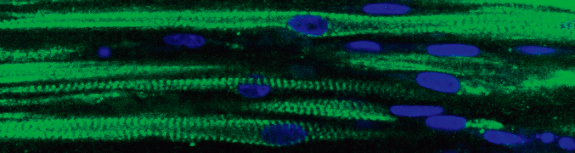

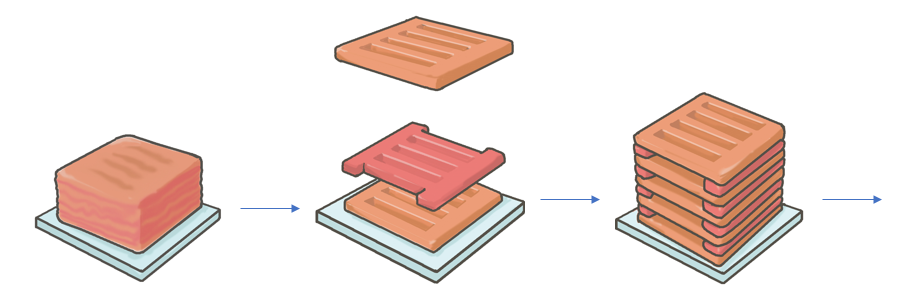

So, how is cultured meat produced? When cells taken from animal muscle are put into a culture fluid containing nutrients such as amino acids and sugars, they respond by moving around freely and coming into contact with one another. Under certain conditions, two cells then fuse into one. Another cell approaches and is fused, and this process is repeated again and again to produce long, thin cells called muscle fibers. These fibers are then bundled together, gradually forming a mass that becomes the basic structure of muscle tissue. Up to now we have successfully created this muscle tissue, but its thickness remains a problem. We cannot yet culture a thick chunk of meat.

If the meat is thin, the culture fluid can permeate throughout, keeping all the cells healthy. If, however, the thickness increases to one to two centimeters, the culture fluid cannot reach the cells at the center of the meat, and they steadily die as the culturing proceeds. Significant questions therefore remain — how to culture the meat for long periods without causing the cells to die, and how to produce it so the muscle fibers are neatly aligned in one direction exactly as they are in a living animal. Despite being well advanced, regenerative medicine has also failed thus far to externally create cell-based organs with exactly the same structure and functionality as the real thing. We are now just taking our first steps.

Challenges from technology, eating habits and regulations

In March 2022, we successfully produced “edible cultured meat,” containing only food-permissible components, in cooperation with Nissin Foods Holdings. Cultured from beef muscle cells, this meat was about one millimeter thick. After boiling it, we sampled the flavor — unfortunately, it didn’t taste like beef. A genuine sample of boiled beef tasted faintly of beef, but there was no such flavor at all in the cultured one. Why was that? I think it might have something to do with the iron content or the fat in the meat, but from where the flavor originates remains a mystery for now.

Challenges still need to be overcome in the areas of technology development, the adjustment of eating habits and the creation of regulations. We need to successfully produce cultured meat with not just the same constitution as in the living animal, but also in an efficient and inexpensive way that produces a delicious product. Then, to widen its appeal, we must create proper regulations and encourage the public to accept cultured meat as part of their diet. Singapore is a leading proponent of cultured meat, and their government has already approved cultured chicken meat for food consumption, with products such as “cultured meat chicken nuggets” on sale there. The Netherlands has also recently approved trials for the consumption of cultured meat. Japan therefore risks falling behind unless it comes up with its own plans for cultured meat.

Utilizing culture techniques to create humanlike robots

Our research on cultured meat came about from our lab’s aim to create human-looking robots. We are investigating how to culture muscle, nerve tissue and skin from materials that must be of human origin. When cultured skin is used to cover a human-shaped robot, the result is a skin with a human-like texture that can be restored to its original form if damaged. In the future, it might be possible to install various sensors to enable the robot’s skin to sense temperature and even to incorporate a sense of touch. By thinking of cells as raw materials, we can open up a whole new way of producing things. To accomplish more humanlike motion, we would like to create a biohybrid robot that uses muscles to move. I think that research into cultured meat can help us to produce such muscles.

When creating a robot, we must also consider how to minimize the negative impact it has on the environment until its disposal. In the case of a biohybrid robot, the biologically sourced main components basically will decompose in the ground, and a new robot can be made by attaching a fresh set of biological components to the remaining parts. Furthermore, when living organisms are used to create artificial objects, the objects may change shape or develop other differences over time, as they are made of living things. How should these kinds of objects be treated in the manufacturing process? Such considerations are precisely why I believe that “cell-based monozukuri (manufacturing)” is one area that the field of mechanical engineering should tackle in the future.

Baiyoniku to wa Nani ka? (“What is cultured meat?”)

(Iwanami Shoten, 2022)

Intended for the general public, this book (an Iwanami booklet) features an easy-to-understand introduction to the research background, state-of-the-art technologies and future issues concerning cultured meat.

* This article was originally printed in Tansei 46 (Japanese language only). All information in this article is as of March 2023.