Management Studies that Work to Ensure the Stability and Strengthening of Local Communities and Industries

Takahiro Fujimoto

Professor

Graduate School of Economics

For a quarter of a century, Professor Fujimoto has worked to advance Manufacturing Management Studies, a discipline with origins in manufacturing sites (genba) such as plants and development facilities. After devoting the first half of his research life to formulating the necessary hypotheses, he has performed proof-of-concept experiments in a variety of settings to test these hypotheses since 2005. Read his words and experience the solid effect of this “Positive Social Science of the Factory Floor” which leads to the stability and strengthening of local communities and industries.

After graduating from the Faculty of Economics at the University of Tokyo, I spent the first half of the 1980s working for a private company in charge of conducting on-site surveys. During the late 1980s, I had the good fortune of becoming a doctoral student at Harvard University, where I pursued research into the principles of technology and operations management. I returned to Japan in 1990 and became an academic staff member of the Faculty of Economics at UTokyo. More than a quarter of a century has passed since then. Although I was in charge of “business administration” at the Faculty, I have in fact been teaching students at both the Faculty and the Graduate School about Technology and Operations Management, or Manufacturing Management, an academic field which originates in plants and development facilities; in other words, straight from the factory floor.

The 25 years I have worked as an academic staff member overlap with the period during which factory wages in Japan have been roughly 20 times higher than those in China. Essentially, Chinese factories, with their low wages, have been enjoying a generous handicap in the global economy, while many of the Japanese factories have struggled to compete, but have eventually somehow pulled through. In the first half of this period, which lasted until around 2005, I attempted to establish the concept of “Manufacturing (Monozukuri) Management” and to formulate my hypotheses. The years following 2005 comprised the period during which I conducted my proof-of-concept experiments.

During the second phase, the proof-of-concept experiment phase, we received funding from the national budget to establish the Manufacturing Management Research Center (MMRC) within the University of Tokyo. The MMRC has conducted proof-of-concept experiments with regard to the following two hypotheses: 1) Manufacturing knowledge can be shared across industries (Manufacturing Management Consortium), and 2) a program for training “Manufacturing Instructors” to improve the flow of value-carrying design information at manufacturing sites will lead to their heightened industrial competitiveness in local areas (Manufacturing Instructor Training School).

-

Added value dwells in the design information

Added value dwells in the design information

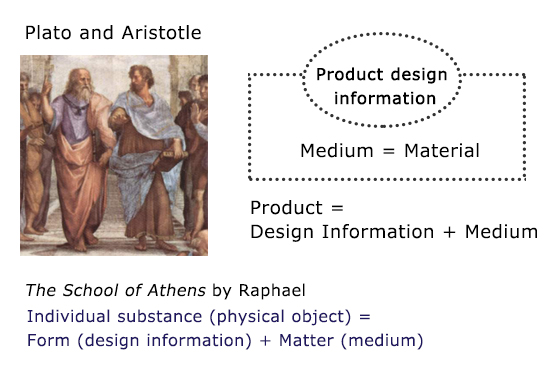

A “product” is the design information transferred to a medium (i.e., a material object)

In Manufacturing Management Studies, focus is placed more on “design information” rather than “medium,” and researchers try to ascertain the value added that resides in design. Design information is considered to be the main source of value added of a product, with the medium as the instrument through which the design information is conveyed. -

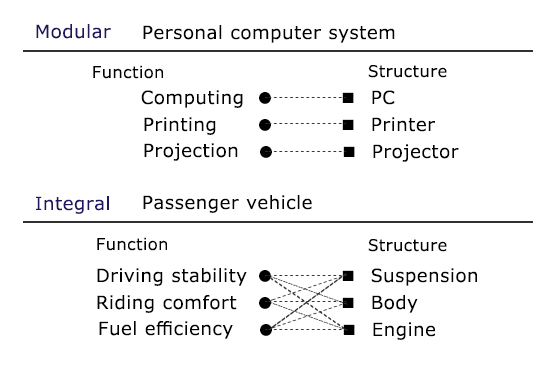

Modular Architecture (one function corresponding to one form) and

Modular Architecture (one function corresponding to one form) and

Integral Architecture (all functions corresponding to all forms)

Compared to the above architecture of simply having one-to-one correspondence between functional and structural elements of an artifact, the below architecture requires complex many-to-many correspondence between them. Japan’s design-based comparative advantages tend to have been observed in products with the latter architecture.

Incidentally, the Manufacturing Management Research Center is currently able to cover its annual budget of several tens of millions of yen with its own business revenues from the industrial sector, without relying upon government or university funds. I believe this proves that this organization, as well as the positive social science of the factory floor behind it, is at least to some extent contributing to the public good.

Question: Is your research useful?

Answer: My other activities include offering support for the revival of local industry, providing instruction for the improvement of manufacturing sites, and changing the awareness of small- and medium-sized business owners. I also receive many requests for advice from international organizations and corporations overseas.

(We have asked twelve professors who contributed articles to this issue to answer the above question in 60 words or fewer. Professor Fujimoto's response appears here.)

Note: This article was originally printed in Tansei 33 (Japanese language only).